Who Else Wants Tips About Can PLC Run Without SCADA

PLC To Start Or Stop 3 Machines Using 1 Switch Basic Exercises

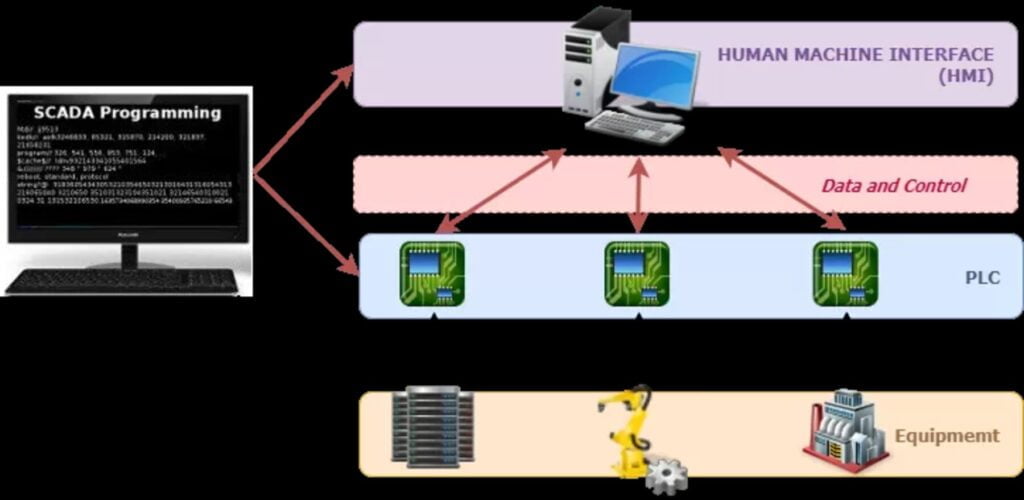

Understanding PLCs and SCADA

1. What exactly are we talking about here?

Let's start with the basics. A PLC, or Programmable Logic Controller, is essentially a ruggedized computer used to automate industrial processes. Think of it as the brains behind the operation, controlling machinery, assembly lines, and all sorts of other equipment. They're designed to withstand harsh conditions — extreme temperatures, vibration, and electrical noise — that would make a regular computer throw in the towel. PLCs make decisions based on pre-programmed instructions, reacting to input signals from sensors and activating outputs to control various devices.

Now, SCADA, or Supervisory Control and Data Acquisition, is a system that provides a bird's-eye view of an entire industrial operation. Imagine a control room where operators can monitor and control processes happening in multiple locations, perhaps even across a vast geographic area. SCADA systems collect data from PLCs (and other devices), visualize it on a screen, and allow operators to send commands back to the PLCs to make adjustments or take corrective actions. It's the big picture monitoring and management tool.

So, PLCs handle the local, real-time control, while SCADA provides the centralized monitoring and supervisory control. They often work together, but they don't necessarily have to. That's the crux of the question we're tackling.

Think of it like this: a PLC is like a smart thermostat controlling the temperature in your home. A SCADA system is like a central energy management system that monitors and adjusts the temperature settings in all the homes in a neighborhood to optimize energy consumption. One can function perfectly well without the other, but they can also work together to create a more efficient and integrated system.

The Core Question

2. The answer, in short

The honest answer is a resounding yes! PLCs are designed to operate independently. They are capable of executing their programmed logic and controlling connected devices without any reliance on a SCADA system. In many smaller applications, a SCADA system is simply unnecessary. If a single PLC is controlling a relatively simple process, there's often no need for the overhead and complexity of a SCADA system.

Consider a simple example: a PLC controlling a water pump based on level sensors in a tank. The PLC receives signals from the sensors, determines whether the tank is full or empty, and then turns the pump on or off accordingly. This entire process can happen autonomously, with the PLC making all the decisions without any intervention from a SCADA system. No outside supervisor needed for this little gig.

The key is understanding the scope and complexity of the application. If you have a single, self-contained process that doesn't require remote monitoring or centralized control, a PLC can handle it just fine on its own. Think of it as a trusty, reliable worker who doesn't need constant supervision. They just get the job done.

Now, while PLCs can function independently, it's important to remember that SCADA systems offer valuable benefits in larger, more complex applications. The ability to centrally monitor and control multiple PLCs, collect and analyze data, and generate reports can significantly improve efficiency, safety, and overall operational performance. So, it's not always a question of can a PLC run without SCADA, but rather should it?

When a PLC is Happy Being a Lone Wolf

3. Scenarios where SCADA is optional

There are several situations where using a PLC without SCADA is not only feasible but also often the most practical and cost-effective solution. One common scenario is in small-scale automation projects. For example, a PLC controlling a single machine in a manufacturing plant or automating a simple process in a small building might not warrant the investment and complexity of a SCADA system.

Another situation is when the process being controlled is relatively simple and doesn't require remote monitoring or control. Think of a PLC controlling a lighting system in a small warehouse or managing the temperature in a single room. In these cases, the benefits of SCADA are minimal, and the PLC can easily handle the task on its own.

Furthermore, if the data generated by the PLC is not critical for overall business operations or doesn't need to be stored and analyzed for historical trends, a SCADA system might be overkill. For instance, a PLC controlling a simple conveyor belt might only need to track basic metrics like the number of items moved, which can be displayed locally without the need for a centralized SCADA system.

Ultimately, the decision of whether to use a PLC with or without SCADA depends on a careful assessment of the specific application requirements. Factors to consider include the complexity of the process, the need for remote monitoring and control, the importance of data logging and analysis, and the overall budget for the automation project. Sometimes, less really is more, especially if it saves you headaches and money.

Can A Schneider Electric SCADAPack Run More Than 2 Apps YouTube

The Benefits of Adding SCADA to the Mix

4. Why sometimes you need the extra help

While PLCs can certainly operate independently, integrating them with a SCADA system unlocks a whole new level of capabilities and benefits, especially in larger and more complex industrial environments. Imagine a sprawling factory floor with dozens of PLCs controlling various machines and processes. A SCADA system provides a central hub for monitoring all of these PLCs, allowing operators to quickly identify and respond to any issues that may arise.

One of the key advantages of SCADA is its ability to collect and visualize data from multiple PLCs in real-time. This provides operators with a comprehensive overview of the entire operation, allowing them to make informed decisions and optimize performance. For example, a SCADA system can track key performance indicators (KPIs) such as production output, energy consumption, and equipment uptime, and display them in easy-to-understand dashboards. This allows managers to quickly identify areas for improvement and take corrective actions.

SCADA systems also enable remote monitoring and control of PLCs. This is particularly useful for operations that are geographically dispersed or require 24/7 monitoring. Operators can access the SCADA system from anywhere with an internet connection, allowing them to respond to alarms and make adjustments even when they are not physically present at the site.

Furthermore, SCADA systems offer advanced features like historical data logging, reporting, and alarm management. Historical data can be used to analyze trends, identify bottlenecks, and optimize processes over time. Reports can be generated to track performance, identify areas for improvement, and comply with regulatory requirements. Alarm management features ensure that operators are notified of any critical events or abnormal conditions, allowing them to respond quickly and prevent costly downtime.

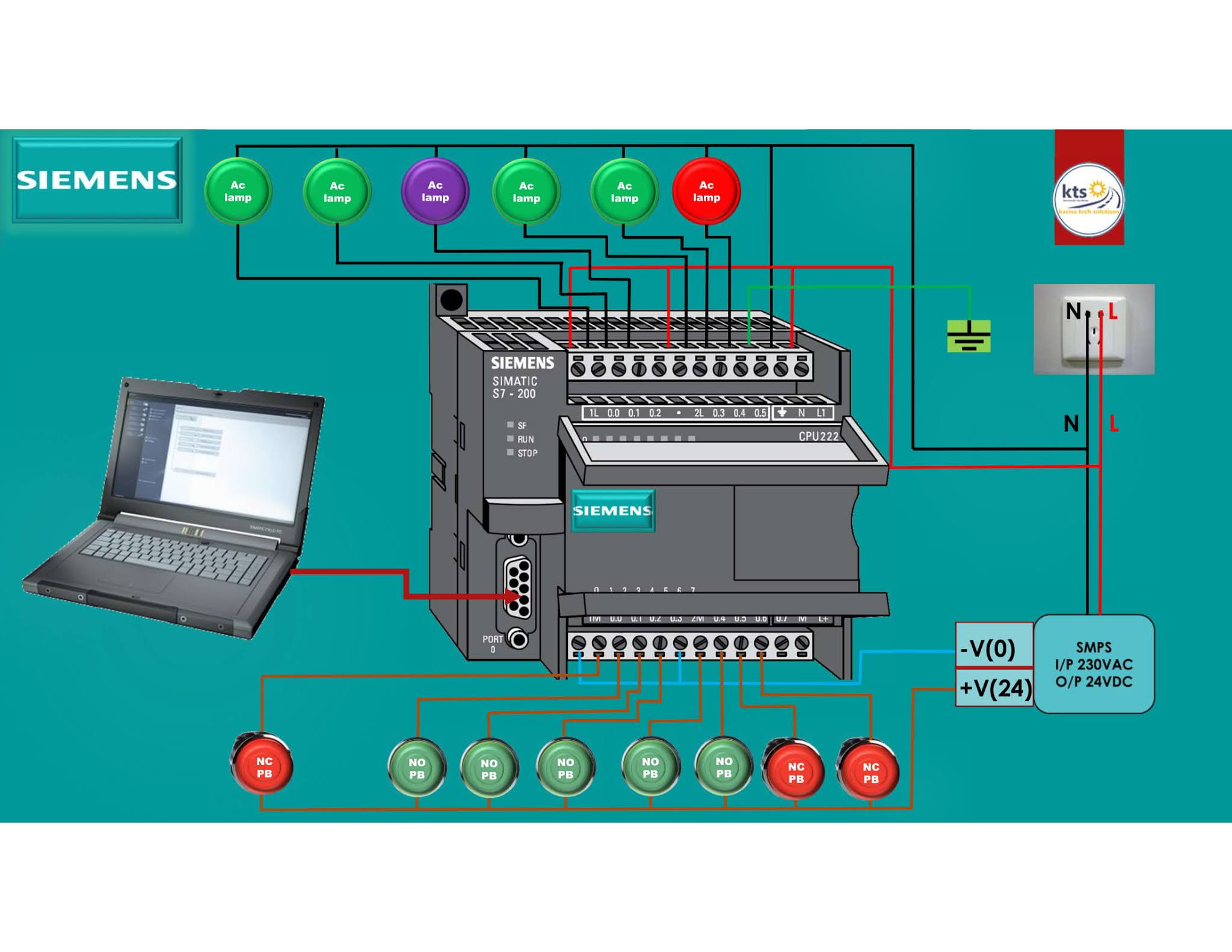

How Wire A Light From Plc

Making the Right Choice for Your Application

5. Weighing the Options

Choosing whether to run a PLC with or without a SCADA system really boils down to understanding your specific needs and priorities. There's no one-size-fits-all answer; it's all about finding the right balance between functionality, cost, and complexity. Think of it as choosing the right tool for the job — a screwdriver is great for tightening screws, but you wouldn't use it to hammer a nail.

Consider the scale of your operation. Is it a small, self-contained process with a single PLC, or a large, complex network with multiple PLCs scattered across a wide area? If it's the former, a standalone PLC might be perfectly adequate. But if it's the latter, a SCADA system can provide invaluable centralized monitoring and control capabilities.

Think about the level of data you need. Do you simply need to control the process, or do you also need to collect and analyze data for performance tracking, reporting, and optimization? If data is critical, a SCADA system can provide the necessary infrastructure for data logging, visualization, and analysis.

Finally, consider your budget and technical resources. SCADA systems can be expensive to implement and maintain, and they require specialized expertise. If you have limited resources, a standalone PLC might be a more practical option. However, if you have the budget and expertise, the benefits of SCADA can often outweigh the costs.