Exemplary Tips About Is More PCB Layer Better

The Layer Cake of Electronics

1. Why the number of layers matters in PCB design

Printed Circuit Boards, or PCBs, are the unsung heroes of modern electronics. Theyre the backbone upon which all those shiny gadgets we love — from smartphones to smart refrigerators — are built. But have you ever stopped to think about what goes into making one? Specifically, how many layers are ideal? Is more PCB layer better? That's what we're diving into today. Forget the technical jargon for a moment; imagine a PCB like a multi-layered cake, each layer serving a specific purpose. Some carry power, others transmit signals, and some act as ground planes, providing a stable reference point. The number of layers affects everything from performance to cost, so its definitely worth understanding.

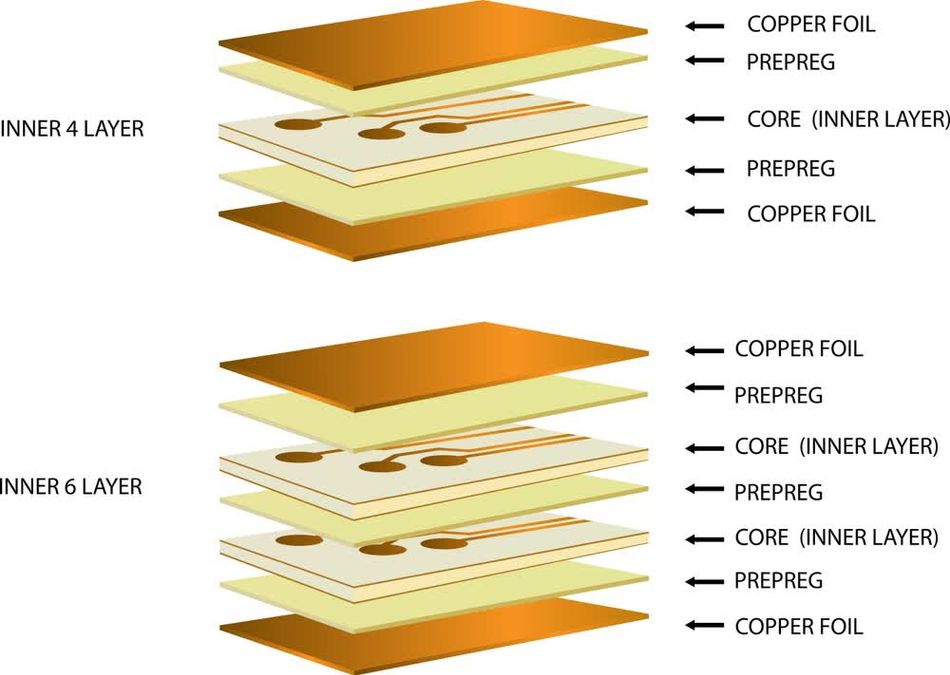

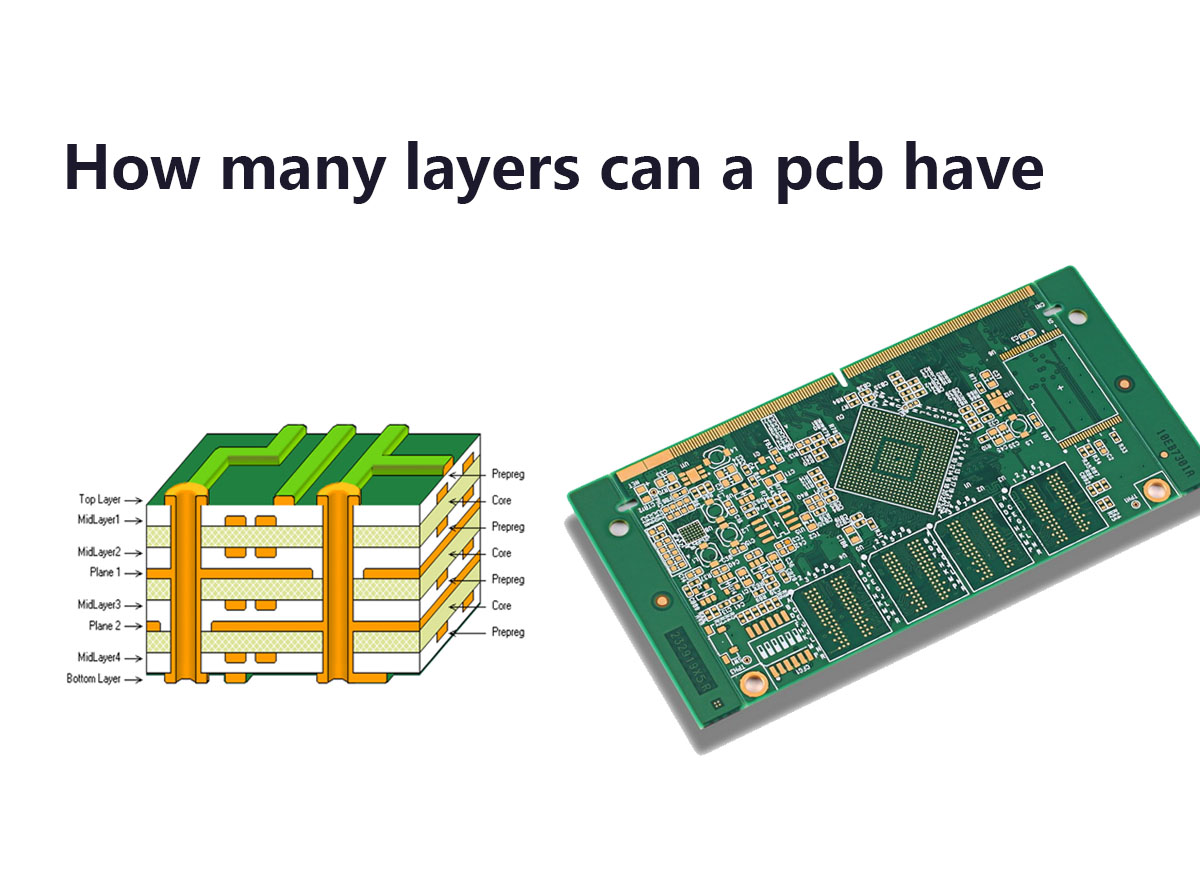

The simplest PCB is a single-layer board, with all the components and copper traces on one side. These are great for simple circuits, like a basic LED flasher. But when you start adding complexity, things get tricky. Routing all those connections on a single layer becomes a real headache, and you might end up with a rat's nest of wires. That's where multi-layer boards come in. By stacking multiple layers on top of each other, connected by vias (tiny holes that allow signals to pass through), you can create much more complex circuits.

Now, picture a four-layer board. You've got two signal layers on the outside and two inner layers, typically used for power and ground. This setup offers better signal integrity and reduced electromagnetic interference (EMI) compared to a single-layer board. As you go up in layer count — six, eight, ten layers, or even more — you gain even more flexibility in routing, improved signal integrity, and better heat dissipation. However, with increased complexity comes increased cost and manufacturing challenges. Deciding on the layer count is a balancing act between performance requirements and budget constraints. It's like choosing the right number of sprinkles for your cake — you want enough to make it delicious, but not so many that it becomes overwhelming!

Essentially, it's a trade-off. More layers can be better, allowing for more complex designs, better signal management, and improved power distribution. Think of it like this: a single lane highway might be fine for a few cars, but a multi-lane freeway is necessary to handle heavy traffic. Similarly, a complex electronic device needs multiple layers on its PCB to manage the flow of signals and power efficiently. But, like building that freeway, more layers also mean higher construction costs and increased complexity in design and manufacturing. It's all about finding the sweet spot that meets the project's needs without breaking the bank. Next, we will discuss about the advantages and disadvantages in more detail.

The Upsides of Stacking High

2. Exploring the benefits of higher layer counts in PCB design

Lets be honest, who doesn't love a good stack? Whether it's pancakes or PCB layers, there's something satisfying about a well-constructed stack. In the PCB world, adding more layers isn't just for show; it brings some serious advantages to the table. So, what are these perks of going multi-layered? One of the primary benefits is improved signal integrity. With more layers, you can dedicate specific layers to ground and power planes, creating a stable and consistent reference voltage. This helps to minimize signal reflections and crosstalk, leading to cleaner signals and better performance. Think of it like creating separate lanes on a highway to prevent cars from bumping into each other — only for electrical signals.

Another key advantage is increased routing density. As electronic devices become smaller and more complex, the need to pack more components into a smaller space increases. More layers provide more routing channels, allowing you to connect all those tiny components without creating a tangled mess of wires. It's like adding more shelves to a bookcase — you can fit more books in the same amount of space. Furthermore, PCBs with higher layer counts typically have better heat dissipation characteristics. The additional copper planes can act as heat sinks, helping to spread heat more evenly across the board and prevent hotspots. This is especially important for high-power applications, where overheating can lead to component failure and reduced performance.

Higher layer counts also allow for better power distribution. You can dedicate specific layers to power and ground, creating a low-impedance power delivery network. This helps to minimize voltage drops and noise, ensuring that all components receive a stable and clean power supply. It's like having a dedicated power grid for your electronics, ensuring that everyone gets the juice they need. Moreover, the isolation between signal layers improves. Think of having soundproofing between rooms — the more layers, the less interference between different signals, resulting in a cleaner and more reliable circuit.

In summary, opting for more PCB layers offers a compelling array of benefits: enhanced signal integrity, greater routing density, superior heat dissipation, and robust power distribution. For complex and demanding applications, these advantages can make a significant difference in the performance and reliability of the final product. It is always a good to consider to use more layers when your device more complex, just like complex cities need multiple layer of road. However, don't rush off to order a 20-layer board just yet! There are also some potential downsides to consider, which we will explore in the next section. Its all about finding the right balance for your specific application.

How Many Layers Can A PCB Have

The Flip Side

3. Considering the drawbacks of using more layers in PCB design

So, we've established that more PCB layers can bring a host of benefits, but like anything in life, there's a flip side to the coin. Before you get too excited about stacking up those layers, let's take a look at some of the potential drawbacks. The most obvious disadvantage is increased cost. Manufacturing multi-layer boards is more complex and requires more materials, which translates to higher prices. You're essentially paying for more "cake," so to speak. It is like compare from a regular cake to a 10 layers cake, of course the price much be different.

Another challenge is increased manufacturing complexity. Building a multi-layer board requires precise alignment, lamination, and drilling processes. Any errors in these processes can lead to defects and reduced yield. The more layers you have, the higher the risk of something going wrong. This increased complexity also translates to longer lead times. It takes more time to manufacture a multi-layer board, which can delay your project schedule. It's like waiting for a custom-built car — it's going to take longer than buying one off the lot. Moreover, troubleshooting and rework become more difficult with multi-layer boards. If you need to make changes or repair a defect, it can be challenging to access the inner layers without damaging the board.

Higher layer counts can also lead to increased board thickness, which may not be desirable in all applications. If you're designing a compact device, you might need to prioritize thinness over performance. Furthermore, the increased density of multi-layer boards can make thermal management more challenging. While the copper planes can help dissipate heat, they can also trap heat within the board, leading to hotspots. Therefore, careful thermal design is essential to ensure that the board doesn't overheat. Sometimes, you can imagine it like you are wearing more clothes to keep warm, but if the weather is too hot, it will make your body harder to release the heat.

In conclusion, while more PCB layers offer advantages like improved signal integrity and routing density, they also come with drawbacks such as higher cost, increased manufacturing complexity, and potential thermal management challenges. It's important to carefully weigh these factors and consider the specific requirements of your application before deciding on the optimal layer count. Don't just assume that more is always better; sometimes, less is more. Its all about finding the right balance between performance, cost, and manufacturability. The ideal number of layers depends on your specific design. Lets dig a bit deeper into the considerations that factor into this decision next!

Finding the Sweet Spot

4. Guidance on determining the ideal number of PCB layers for your project

So, how do you decide on the right number of PCB layers? It's not as simple as picking a random number and hoping for the best. It's a decision that requires careful consideration of several factors. Lets break down the key elements to help you find that sweet spot. First and foremost, consider the complexity of your circuit. How many components do you need to connect? How dense are the traces? If you have a simple circuit with few components, a single or double-layer board might be sufficient. But if you have a complex circuit with hundreds of components and dense routing requirements, you'll likely need more layers.

Next, think about signal integrity. Are you dealing with high-speed signals or sensitive analog signals? If so, you'll need to pay close attention to signal integrity to minimize noise and interference. This often requires using multiple layers for ground and power planes, as well as controlled impedance traces. Another important factor is power distribution. How much power does your circuit consume? Do you need to minimize voltage drops and noise in the power supply? If so, you'll need to dedicate specific layers to power and ground planes. Remember, stable power is crucial for reliable performance, just like a stable foundation is crucial for a building.

Another key consideration is cost. As we discussed earlier, more layers translate to higher manufacturing costs. So, you'll need to balance the performance benefits of more layers against the budget constraints of your project. Don't over-engineer your board if you don't need to. Think about manufacturability. Can your chosen manufacturer reliably produce boards with the desired layer count and complexity? Some manufacturers have limitations on the number of layers they can handle, or the minimum trace width and spacing they can achieve. Make sure to check with your manufacturer before finalizing your design.

Essentially, choosing the right PCB layer count is like picking the right tool for the job. A hammer is great for driving nails, but you wouldn't use it to cut a piece of wood. Similarly, a single-layer board might be fine for a simple circuit, but it won't be suitable for a complex, high-speed design. Consider all the factors discussed above, weigh the pros and cons of different layer counts, and choose the option that best meets the needs of your specific application. It is a complicated process, but it is very necessary to have a good product. Now, lets look at how these considerations play out in different real-world scenarios.

What Is The Inner Layer Of A PCB?

Real-World Examples

5. Illustrative scenarios showcasing the impact of PCB layer count choices

To bring these concepts to life, let's explore a few real-world examples of how PCB layer count decisions are made in different scenarios. Imagine you're designing a simple LED flasher for a hobby project. This circuit only requires a few components and low-speed signals. In this case, a single-layer board would be perfectly adequate and cost-effective. There's no need to over-engineer it with multiple layers. It's like using a bicycle to go to the grocery store — it gets the job done without being overkill.

Now, let's say you're designing a complex smartphone. This device contains hundreds of components, high-speed processors, and sensitive RF circuits. Signal integrity is critical to ensure reliable communication and data transfer. In this case, a multi-layer board with at least eight layers (or even more) would be necessary. These layers would be used for ground planes, power planes, signal routing, and shielding to minimize interference. The increased cost and complexity are justified by the performance requirements of the device.

Consider a medical device, such as a heart monitor. This device needs to be highly reliable and accurate. Signal integrity and power distribution are crucial to ensure that the device provides accurate readings and doesn't malfunction. A multi-layer board with dedicated ground and power planes, as well as controlled impedance traces, would be essential. Redundancy and fault tolerance may also be important considerations, which could further increase the layer count. Next is an industrial control system that is responsible for automation.

These scenarios shows how important it is to pick the right number of layers in PCB. As you can see, the ideal PCB layer count depends heavily on the specific application and its requirements. There's no one-size-fits-all answer. By carefully considering the factors we discussed earlier — circuit complexity, signal integrity, power distribution, cost, and manufacturability — you can make an informed decision and choose the layer count that best meets the needs of your project. Consider PCB layers as a tool to build a successful product that can thrive in market.

FAQ

6. Frequently Asked Questions about PCB Layers

Let's tackle some common questions about PCB layers to solidify your understanding.

Q: Is a higher layer count always better for signal integrity?A: Not necessarily. While more layers can provide more flexibility for ground and power planes, which improve signal integrity, proper design and routing are equally important. A poorly designed multi-layer board can actually have worse signal integrity than a well-designed single or double-layer board.

Q: How do I know if I need a ground plane?A: If you're dealing with high-speed signals, sensitive analog signals, or circuits that are susceptible to noise, a ground plane is highly recommended. It provides a stable reference voltage and helps to minimize interference. You can also add more layers on PCB ground.

Q: What's the difference between a via and a through-hole?A: A via is a plated hole that connects two or more layers of a PCB. A through-hole is a plated hole that goes all the way through the board and is typically used for mounting components. In simple words, the through-hole is for placing component while via is for routing current to a different layer.

Q: Can I add layers to an existing PCB?A: No, you cannot add layers to an existing PCB. The layers are laminated together during the manufacturing process. If you need more layers, you'll need to design a new board from scratch.