Supreme Tips About Can You Put A 230V Plug On 110V Drill

The Great Voltage Divide

1. Understanding Voltage Differences

So, you've got a trusty 110V drill and a 230V outlet is staring you down. The question burns: Can you just slap a new plug on that drill and call it a day? Well, hold your horses! This isn't quite as simple as swapping out a lightbulb. We're dealing with electricity, and electricity has rules, often enforced by a grumpy electrical code inspector. Trying to force the issue without understanding the consequences could lead to a smoky, sad drill or, worse, an electrical hazard.

Think of it like this: your drill is designed to sip electricity at a certain voltage level. A 110V drill is expecting a gentle flow. Suddenly, you introduce a 230V surge — it's like trying to force a firehose stream through a drinking straw. Things are bound to go wrong, and usually, spectacularly.

The key concept here is voltage. It's the electrical pressure pushing the current. Devices are built to handle a specific voltage range. Going significantly above that range can damage or destroy the internal components. The keyword here is drill part of speech is a noun.

Before even contemplating a plug change, you absolutely must check the voltage rating on your drill. It's usually printed on a label near the power cord or on the drill itself. If it says "110V-120V," then plugging it into a 230V outlet, even with an adapter, is a recipe for disaster. Think melted circuits and the unmistakable aroma of burning electronics.

The Plug Paradox

2. The Deceptive Simplicity of Plugs

Okay, let's say you're thinking, "But the plugs are different! I'll just use an adapter!" Adapters are handy for fitting different shaped plugs into different shaped outlets, but they do not change the voltage. An adapter merely allows you to physically connect a plug to a socket. It doesn't magically convert 230V electricity into 110V electricity. Using an adapter in this scenario is like putting a square peg in a round hole and hoping for the best. It might fit (with some force), but it's still wrong, and probably damaging.

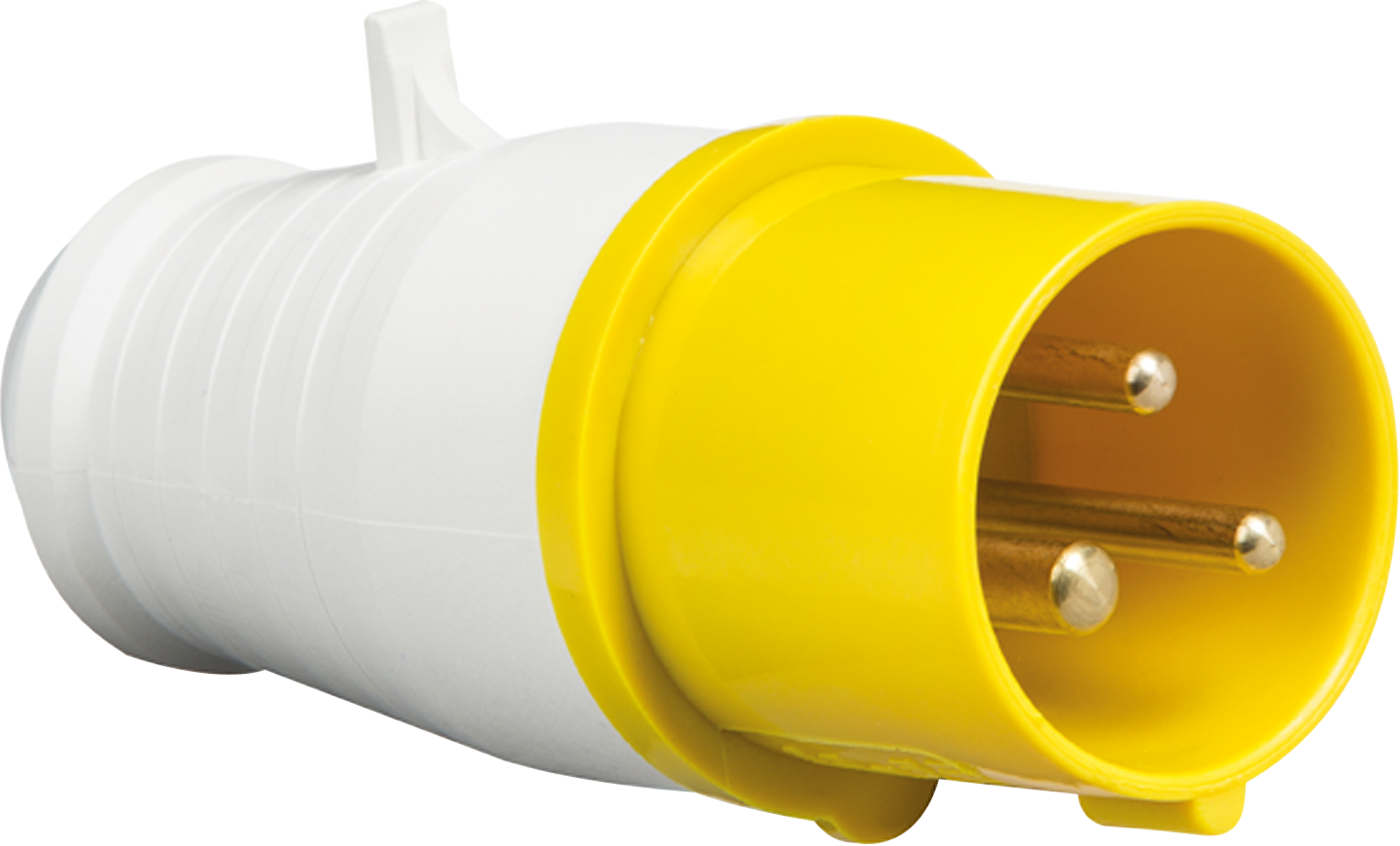

Changing the plug to a 230V-compatible one doesn't make your 110V drill magically compatible either. All you're doing is creating a situation where you can easily plug it into a 230V outlet and fry it. The shape of the plug is simply a physical indicator of the voltage it should be connected to.

The potential for confusion is one reason why electrical codes are so strict. Imagine someone else using your drill later, not realizing it's only rated for 110V, and plugging it into a 230V outlet. Boom! Safety is paramount, especially when electricity is involved. Proper labeling and understanding the voltage requirements of your tools are essential.

Therefore, replacing the plug on a 110V drill with a 230V plug creates a dangerous situation because it allows the drill to be connected to a voltage it is not designed to handle, leading to damage or safety hazards.

Easy Guide To Wiring A 110V Plug

The Transformer Triumphant

3. The Option of a Step-Down Transformer

So, is there any way to use your 110V drill with a 230V outlet? Yes, but it involves a device called a step-down transformer. A transformer is an electrical device that converts voltage from one level to another. A step-down transformer specifically takes a higher voltage (like 230V) and reduces it to a lower voltage (like 110V). It's like a translator for electricity.

However, not just any transformer will do. You need to make sure the transformer is rated for the wattage (power consumption) of your drill. The wattage is usually printed on the drill alongside the voltage rating. Choose a transformer with a wattage rating that is equal to or higher than your drill's wattage to avoid overloading the transformer.

Using a transformer adds an extra layer of complexity (and expense) to your setup. You'll need to plug the transformer into the 230V outlet, then plug your 110V drill into the transformer. It's not as convenient as simply plugging the drill directly into the wall, but it's the only safe way to use your drill without risking damage. Also, a transformer for power tools will be quite heavy and bulky, so keep that in mind for portability.

Think of a step-down transformer as a responsible chaperone for your 110V drill. It keeps the voltage at a safe level, preventing any electrical misadventures. It's a much better option than attempting a plug swap and hoping for the best!

Wiring A 110 Volt Plug

Why Bother? The Case for Buying a Native 230V Drill

4. Considering a 230V Drill Purchase

Now, let's be honest: using a transformer isn't the most elegant solution. It's bulky, adds an extra point of failure, and can be a bit of a hassle to transport. So, you might be wondering if it's just better to buy a new drill that's designed for 230V power. And, in many cases, that's the most sensible option.

A 230V drill will plug directly into your 230V outlets without the need for a transformer. It's a cleaner, more reliable setup. Plus, you won't have to worry about accidentally plugging your 110V drill into a 230V outlet (which, let's face it, is a mistake waiting to happen).

Consider the long-term cost. While a transformer might seem cheaper upfront, a dedicated 230V drill will eliminate the risk of damaging your existing drill and the potential inconvenience of dealing with a transformer. Also, modern 230V power tools are often more energy-efficient than older 110V models, potentially saving you money on your electricity bill in the long run.

Ultimately, the decision depends on your specific circumstances. If you only occasionally need to use a drill and already have a 110V model, a transformer might be a reasonable temporary solution. But if you're a frequent user or if you're setting up a new workshop, investing in a native 230V drill is likely the best way to go for safety, reliability, and convenience.

Safety First

5. Prioritizing Electrical Safety

No matter what you decide to do, remember that electrical safety is paramount. Always disconnect power tools before making any adjustments or repairs. If you're not comfortable working with electricity, consult a qualified electrician. It's better to be safe than sorry, especially when dealing with potentially dangerous voltages.

Double-check all voltage ratings and wattage requirements before plugging anything in. Use properly grounded outlets and extension cords. And never, ever bypass safety devices like circuit breakers or fuses. They're there to protect you and your equipment from electrical hazards.

If you're using a transformer, make sure it's placed in a well-ventilated area to prevent overheating. Inspect the transformer and your drill's power cords regularly for damage. If you see any cracks, fraying, or other signs of wear, replace the cord immediately.

Treat electricity with respect, and it will (hopefully) treat you with respect in return. Remember, a little knowledge and caution can go a long way in preventing electrical accidents. And always remember the golden rule: when in doubt, call a professional.