Ace Info About How To Generate 3 Phase AC From Single

StepbyStep Guide How To Wire A 3 Phase Air Conditioner Wiring

Transforming Single-Phase Power into Three-Phase Muscle

1. Understanding the Need for Phase Conversion

Ever wondered why some machines hum with more power and efficiency than others? A big part of that often comes down to the kind of electricity they're sipping: single-phase versus three-phase. Single-phase is what you usually find in your home, powering your lights, TV, and that ever-humming refrigerator. Its reliable and works great for smaller appliances. But when you start talking about serious industrial equipment, heavy machinery, and applications that demand a consistent, robust power supply, three-phase AC takes the crown. It's like the difference between a bicycle and a freight train — both can get you somewhere, but one is built for sheer power and hauling capacity.

Think of a large factory floor filled with massive motors and complex systems. Running all that on single-phase would be like trying to feed a dinosaur with a teaspoon. It would be inefficient, prone to voltage drops, and potentially damaging to the equipment. Three-phase AC provides a smoother, more consistent flow of power, distributing the load across three separate phases, thus minimizing stress on the electrical grid and ensuring optimal performance of those power-hungry machines. It's the backbone of many industrial operations.

But what if you only have single-phase available, yet you need to run a three-phase motor or piece of equipment? That's where the magic of phase conversion comes in. We're essentially taking the single-phase supply and, through some clever electrical trickery, creating a simulated three-phase output. It's like teaching a one-legged dog to dance — not the easiest thing in the world, but with the right tools and techniques, perfectly achievable.

So, if youre in a situation where your shop or farm has single-phase, but you need that robust three-phase power, don't despair! You don't necessarily have to shell out big bucks to upgrade your entire electrical infrastructure. There are practical ways to generate three-phase AC from a single-phase source. Lets dive in and explore the options, shall we? It's not as daunting as it sounds!

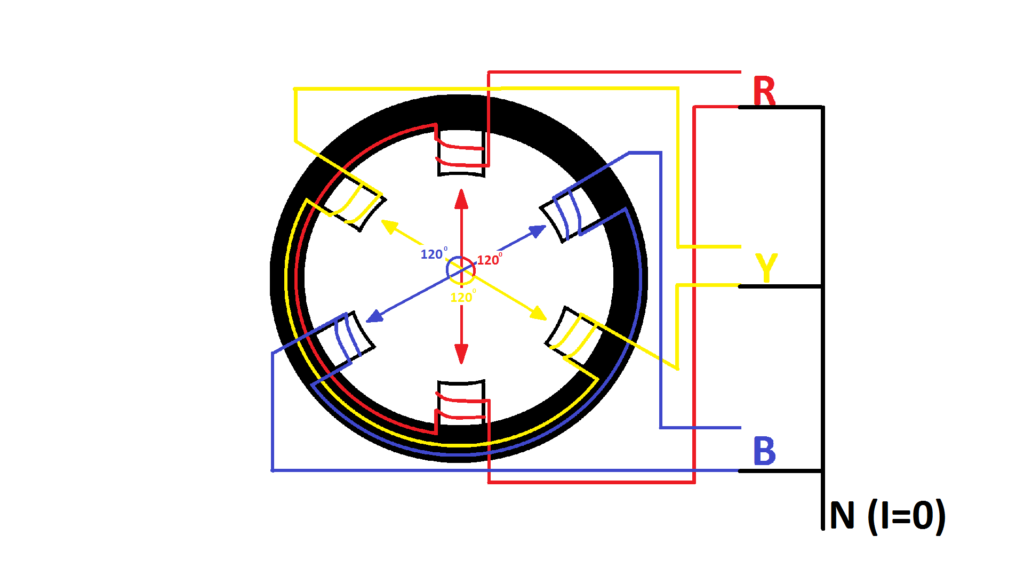

Phase Wiring

Methods for Generating Three-Phase AC from Single-Phase

2. Rotary Phase Converters

One common method involves using a rotary phase converter. Imagine a motor that acts like a mini power plant. This device essentially takes the single-phase input and uses it to spin a generator-like component. This spinning action then creates the three-phase output you need. It's a bit like starting a fire by rubbing sticks together, just a whole lot more technologically advanced and (hopefully) less smoky.

Rotary phase converters are known for their ability to handle heavier loads and provide a more balanced three-phase output compared to some other methods. This makes them a good choice for running multiple machines or equipment with high starting torque requirements, such as CNC machines or air compressors. They are also fairly forgiving in terms of load imbalance, meaning they can handle situations where the load on each of the three phases isn't perfectly equal.

However, rotary converters do have a few quirks. They tend to be larger and noisier than other types of converters. The spinning motor can generate a noticeable hum, so you'll want to consider the location and noise level if you're sensitive to sound. They also require regular maintenance to keep the motor and bearings in good working order. Think of it as a reliable workhorse that needs occasional TLC to keep chugging along.

Choosing the right size rotary converter is critical. Undersizing it can lead to voltage drops and equipment malfunction, while oversizing it is simply a waste of money and space. Consulting with an electrical professional to determine the appropriate size based on your specific needs is always a wise decision. Its like buying shoes — you need the right fit to avoid blisters and discomfort!

3. Static Phase Converters

Static phase converters, on the other hand, are a more compact and less expensive option. They don't involve any moving parts, relying instead on capacitors to create a phase shift in the electrical current. This shift simulates the three-phase output. They're like the minimalist art piece of the phase conversion world — simple, elegant, and (relatively) quiet.

These converters are generally smaller and easier to install than rotary converters, making them a good choice for situations where space is limited or noise is a concern. They're also typically less expensive upfront, which can be attractive if you're on a tight budget. However, there are some drawbacks to consider.

Static converters are typically less efficient than rotary converters and may not be suitable for running equipment with high starting torque requirements. They also tend to provide a less balanced three-phase output, which can lead to reduced motor performance and potential overheating. They are best suited for applications with relatively consistent loads, such as pumps or fans, where the motor doesn't experience sudden changes in demand.

A static phase converter operates by using capacitors to create the necessary phase shift to trick a three-phase motor into running on a single-phase supply. The capacitor values are carefully chosen to approximate a balanced three-phase waveform, but the resulting voltage and current waveforms may not be perfectly sinusoidal. This can lead to increased harmonic distortion and reduced motor efficiency. It's like trying to bake a cake with slightly off measurements — the end result might be edible, but it won't be quite as perfect as it could be.

Variable Frequency Drives (VFDs)

4. VFDs for Phase Conversion and Motor Control

Variable Frequency Drives (VFDs) offer a more sophisticated approach to generating three-phase AC from single-phase. A VFD doesn't just convert the phase; it actually rectifies the single-phase input into DC, and then uses a complex set of electronics to create a synthesized three-phase output with adjustable frequency and voltage. Think of it as a digital artist who can create any power waveform you desire from a single source.

VFDs offer several advantages. They provide precise control over motor speed and torque, allowing you to optimize the performance of your equipment for different applications. They can also improve energy efficiency by reducing motor speed when full power isn't needed. And because they create a synthesized three-phase output, they can provide a very clean and balanced power supply, minimizing stress on the motor.

However, VFDs are generally more expensive than static phase converters and may require some technical expertise to install and program. They also generate some electrical noise, which may require filtering in sensitive applications. But for applications where precise motor control and energy efficiency are paramount, a VFD can be a worthwhile investment.

The ability to adjust the frequency and voltage of the output allows for "soft starting" of motors, reducing inrush current and mechanical stress. This extends the lifespan of the motor and reduces the risk of tripping circuit breakers. VFDs also often include built-in protection features, such as overcurrent and overvoltage protection, which further enhance the reliability of the system. Its like having a personal trainer and a bodyguard for your motor all rolled into one!

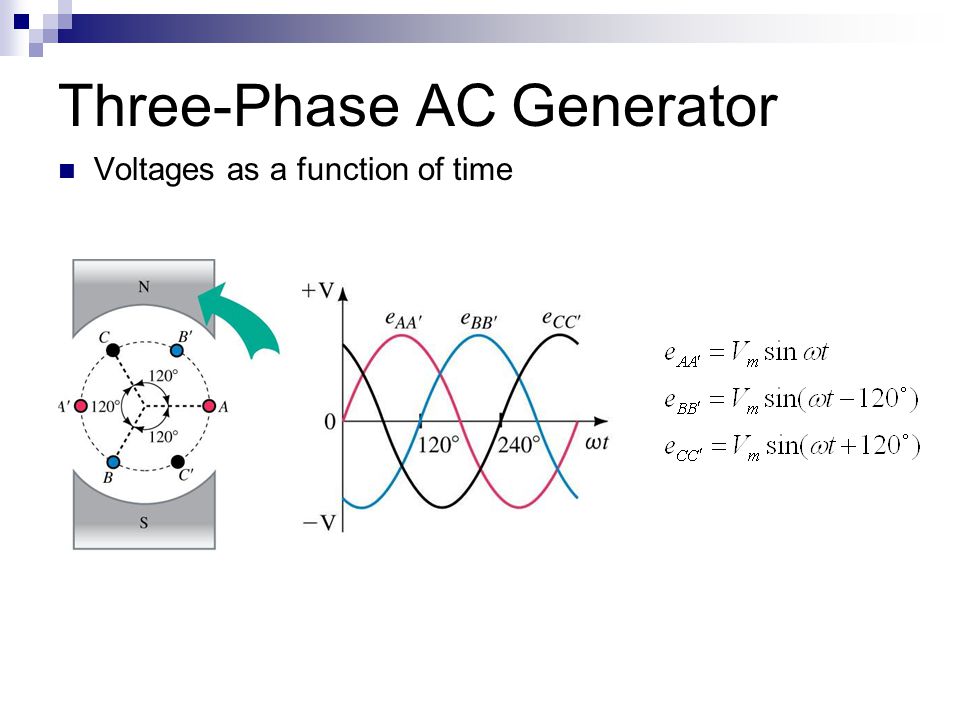

Lesson 33 AC Generators. Ppt Video Online Download

Choosing the Right Solution for Your Needs

5. Factors to Consider When Selecting a Converter

Selecting the right method for generating three-phase AC from single-phase depends on a number of factors, including the size and type of equipment you need to power, your budget, space constraints, and your tolerance for noise. There is no one-size-fits-all answer, and a careful evaluation of your specific needs is essential.

If you need to power heavy-duty equipment with high starting torque requirements, a rotary phase converter is likely the best choice. If you're on a tight budget and only need to run smaller loads, a static phase converter might be sufficient. And if you need precise motor control and energy efficiency, a VFD is the way to go.

Don't forget to factor in the cost of installation and maintenance. Rotary converters require regular maintenance, while VFDs may require some programming expertise. Static converters are generally the simplest to install and maintain, but they may not be suitable for all applications.

It's also important to consider the quality of the single-phase power supply. If your single-phase voltage is unstable or prone to fluctuations, it can affect the performance of the phase converter. In such cases, you may need to install a voltage regulator or other power conditioning equipment to ensure a stable and reliable three-phase output. It's like ensuring you have the right ingredients before you start baking — a good recipe won't save you from bad ingredients!

Safety First! Electrical Considerations

6. Prioritizing Safety in Phase Conversion

Working with electricity can be dangerous, so it's crucial to prioritize safety when installing and using any type of phase converter. Always disconnect the power supply before working on electrical equipment, and follow all applicable electrical codes and regulations. Wear appropriate personal protective equipment, such as safety glasses and insulated gloves, and never work on electrical equipment when you're tired or distracted.

Ensure that the phase converter is properly grounded to prevent electrical shock hazards. Use appropriately sized wiring and circuit breakers to protect against overloads and short circuits. And if you're not comfortable working with electricity, hire a qualified electrician to perform the installation.

Regularly inspect the phase converter and associated wiring for signs of damage or wear. Replace any damaged components immediately. And never attempt to repair electrical equipment unless you're qualified to do so. Electricity is not something to be taken lightly, and a little bit of caution can go a long way in preventing accidents.

Pay attention to ventilation. Phase converters, especially rotary models, generate heat. Make sure the unit has adequate ventilation to prevent overheating, which can damage the equipment and create a fire hazard. Its like making sure your cars radiator has enough coolant keep things cool to avoid a meltdown!